- Call Now +91 7624093767

- Send Us An Email

marketing1@rajfilters.com

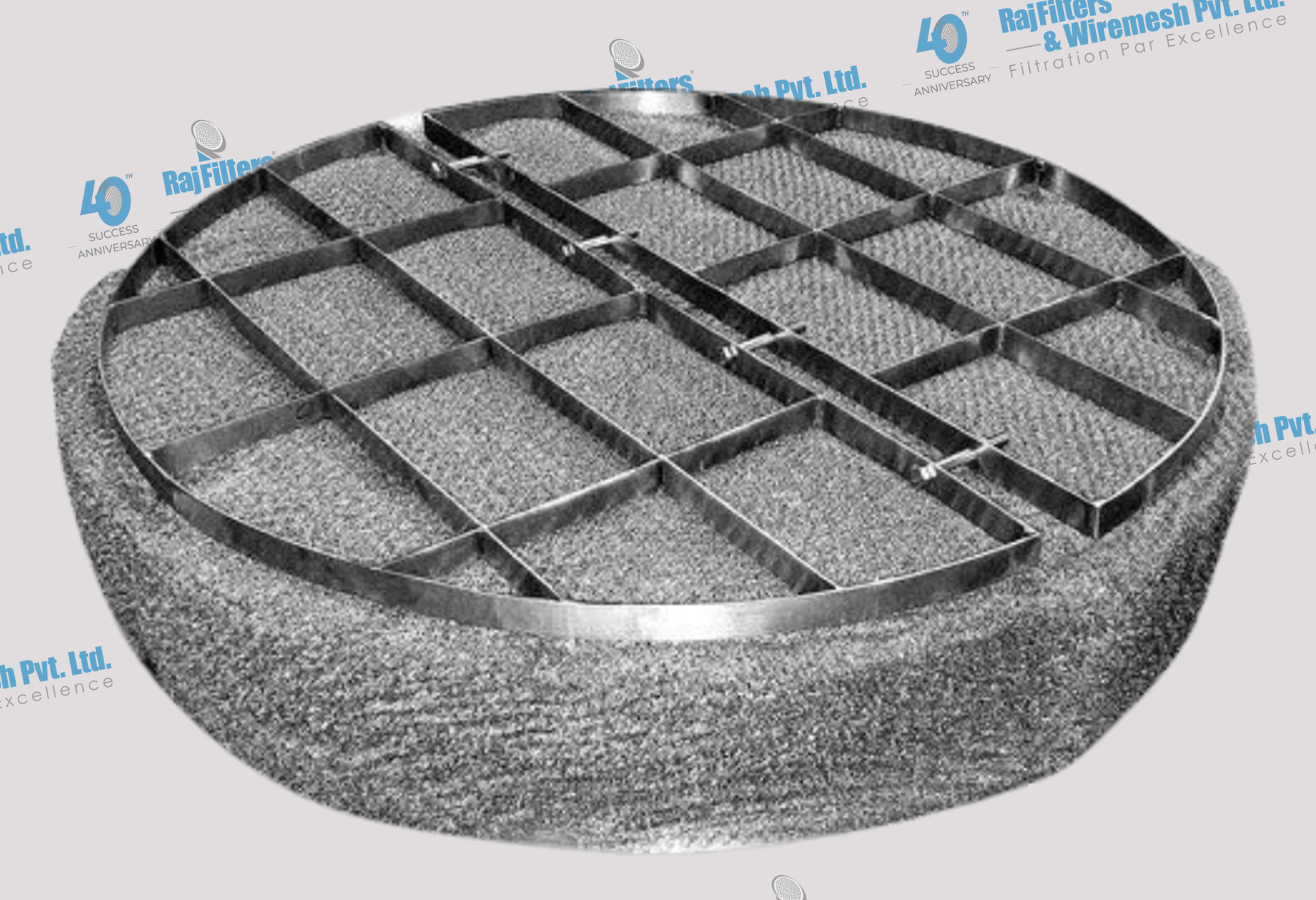

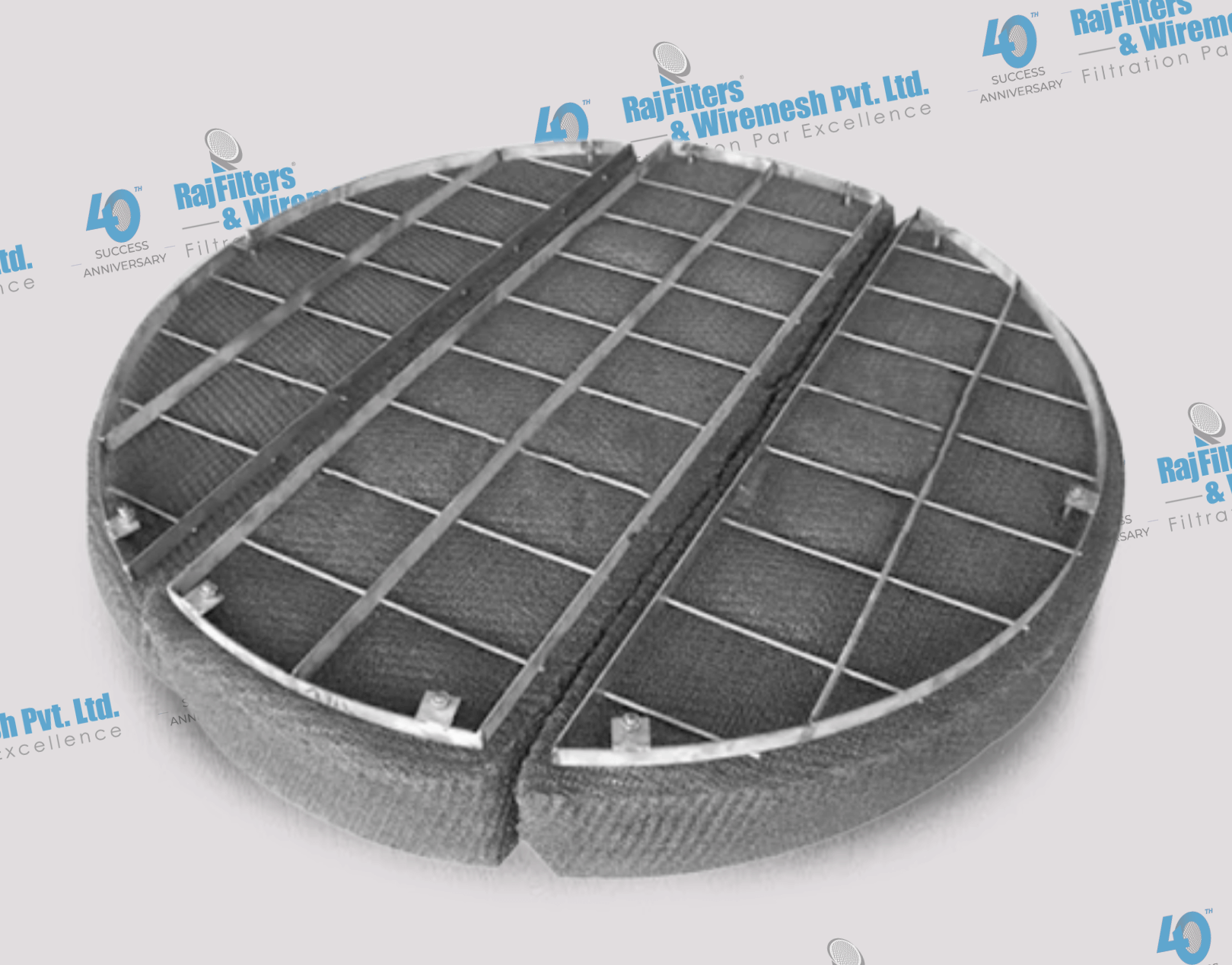

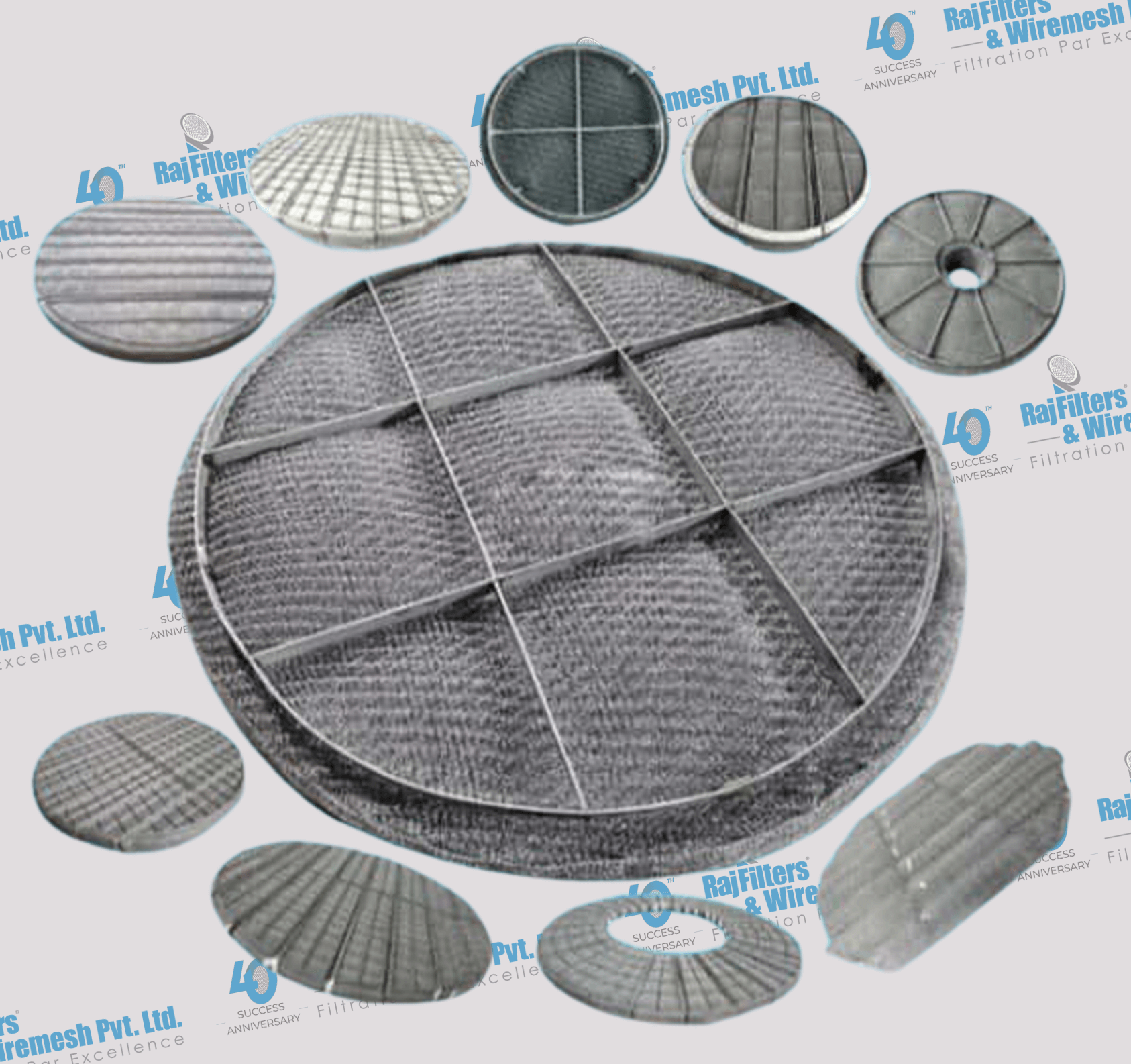

Overview of Demister Pads

When it comes to filtration reliability, our top quality demister pads set the benchmark. Designed for durability and precision, they deliver outstanding performance in demanding environments.

At RajFilters, we specialise in manufacturing high-efficiency SS wire mesh demister pads, engineered to separate fine liquid droplets from gas or vapour streams. These mist eliminators are essential in industries like oil & gas, chemical processing, power plants, and pharmaceuticals, where mist-free gas is crucial for protecting equipment and improving product quality.

What is a Demister Pad?

A demister pad (also known as a mist eliminator or mesh pad) is a woven stainless steel mesh structure designed to trap and blend fine liquid droplets from process gases. As the gas-carrying mist passes through the mesh, the filaments capture droplets, merge into larger drops, and drain away, ensuring a clean and dry gas output.

- Removes droplets ≥ 3–5 μm with up to 99.9% efficiency

- Reduces carryover, corrosion, and contamination

Applications of Demister Pad

Our demister pads are trusted and used across a wide range of industries:

| Industries | Applications |

| Oil & Gas | Knockout Drums, Separators And Compressor Protection |

| Chemical Plants | Absorbers, Scrubbers, Acid Mist Removal |

| Pharmaceuticals | Sterile Gas Systems, Solvent Recovery Units |

| Power Plants | Steam Turbine Inlet Protection, Cooling Towers |

| Desalination | Brine Mist Elimination, Evaporators |

| Food & Beverage | Hygienic Gas Filtering In Process Equipment |

How Demister Pads Work?

Why Choose RajFilters & Wiremesh Pvt. Ltd.?

Looking for A Top-Quality Demister Pad?

Looking for A Top-Quality Demister Pad?

Let us help you to eliminate mist, protect your equipment, and optimise your process with a custom-made SS wire mesh demister pad.

FAQs

FAQs

Q1. What is a demister pad?

A demister pad is designed to remove entrained liquid droplets from gas

streams, protecting downstream equipment and improving overall process

efficiency.

Q2. Where are demister pads used?

Demister pads are widely used in petrochemical plants, chemical processing

units, gas scrubbing systems, and solvent recovery operations.

Q3. What materials are available?

We supply demister pads in various stainless steel grades and specialty

alloys to withstand corrosive environments and high-temperature operating

conditions.

Q4. Can demister pads be engineered for specific process conditions?

Yes. Demister pads can be customized in terms of thickness, mesh type, and

configuration to deliver optimal separation efficiency for specific

process requirements.